Manufacturing

High-Reliability Manufacturing for Aerospace, Defence and Space Systems

Specification

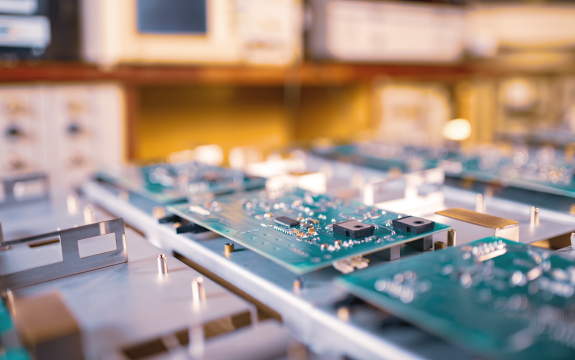

Intelligent Manufacturing

CoreEL excels in intelligent manufacturing, leveraging advanced technologies like automation, AI, and IoT to optimize production processes. We integrate smart systems that enhance efficiency, reduce costs, and improve product quality across all stages of manufacturing. With a focus on real-time data analytics and seamless process integration, we enable clients to achieve greater flexibility and scalability in their operations, meeting the demands of today’s fast-paced markets.

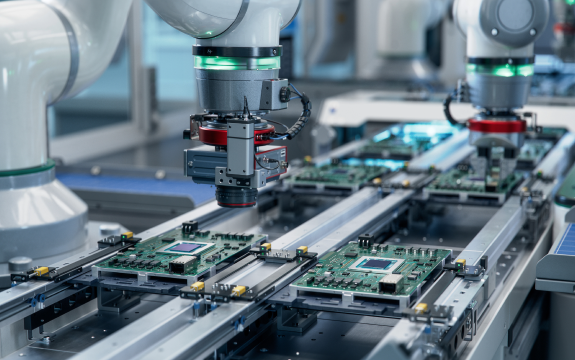

Automated Manufacturing

CoreEL specializes in automated manufacturing solutions that streamline production processes and enhance operational efficiency. By incorporating cutting-edge robotics, AI, and advanced automation technologies, we reduce human error, improve consistency, and accelerate time-to-market. Our expertise enables us to deliver scalable and cost-effective solutions, ensuring high-quality output while minimizing production costs and downtime.

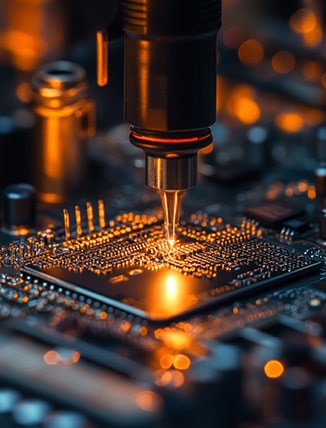

Fast Manufacturing

CoreEL excels in fast manufacturing, delivering rapid turnaround times without compromising on quality. By utilizing advanced automation, streamlined processes, and agile production techniques, we ensure quick production cycles while maintaining precision and reliability. Our expertise allows us to meet tight deadlines and accelerate time-to-market, helping clients stay competitive in fast-paced industries.

Zero Defect Manufacturing

Why CoreEL for Smart Manufacturing?

Well experienced Procurement, Assembly, Testing, and Quality team

Well established ecosystem for Components, PCB, Enclosure, and PCB assembly

EN9100 and ISO13485 approved PCB suppliers, Enclosure fabricators, and PCB assembly houses

Extensive electrical, functional, integration, and stress testing experience

Experience working with boards up to 30 layers and rigid-flex-rigid boards

Mechanical enclosure and cable harnessing development, fabrication, and integration

Experienced team to qualify the product as per customer-required standards like Mil PRF, UL, CS, and CE

Well-experienced board debug and rework teams which in turn decrease the time to market

Manufacturing Facilities

Fully equipped hardware test facilities-

Burn In and Thermal Cycling

Spectrum analyzers

Function generators

Digital Storage oscilloscopes

Logic analyzers

High-end bench power supplies

Contact to Expertise in the manufacturing industry

Manufacturing Facilities

Burn In and Thermal Cycling

Spectrum analyzers

Function generators

Digital Storage oscilloscopes

Logic analyzers

High-end bench power supplies

Smart Manufacturing

- Well experienced Procurement, Assembly, Testing, and Quality team

- Well established ecosystem for Components, PCB, Enclosure, and PCB assembly

- EN9100 and ISO13485 approved PCB suppliers, Enclosure fabricators, and PCB assembly houses

- Extensive electrical, functional, integration, and stress testing experience

- Experience working with boards up to 30 layers and rigid-flex-rigid boards

- Mechanical enclosure and cable harnessing development, fabrication, and integration

- Experienced team to qualify the product as per customer-required standards like Mil PRF, UL, CS, and CE

- Well-experienced board debug and rework teams which in turn decrease the time to market

- Well-defined RMA (Return Material Authorization) process