Enabling Safety-Critical Verification for Avionics and Aerospace Designs

DO-254, the industry standard for airborne electronic hardware, requires rigorous verification, traceability, and documentation to ensure safety and reliability. Siemens EDA offers a comprehensive suite of tools that support DO-254 objectives across the entire design and verification lifecycle—from linting and formal property checking to traceability, coverage closure, and equivalence checking.

Key Tool Support for DO-254 Workflows:

- A lightweight, non-intrusive requirements traceability tool that connects design, verification, and test artifacts.

- Provides full traceability from requirements to verification results—supporting DO-254 objective-based audits and documentation.

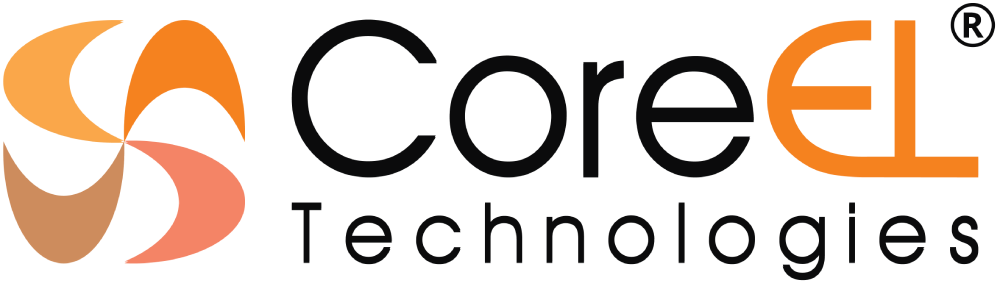

- Fast, push-button RTL static analysis to detect structural and style violations early.

- Supports DO-254 early lifecycle reviews with pre-configured check sets for safety-critical coding standards.

- Automatic detection of complex sequential RTL issues such as FSM deadlocks and arithmetic overflows.

- Identifies hard-to-find logic bugs without simulation, aligning with DO-254 requirements for robustness.

- Assertion-based formal verification to exhaustively prove that design properties hold across all legal scenarios.

- Ensures traceable, deterministic verification for safety-critical logic without relying on testbenches.

- Automated detection of clock domain crossing issues like metastability and synchronization failures.

- Addresses asynchronous communication concerns—a key audit requirement in DO-254.

- Verifies functional equivalence between RTL and synthesized netlist or ECO-modified versions.

- Validates consistency of design intent throughout the toolchain, a critical DO-254 goal.

- Automatically identifies unreachable code and helps close code coverage gaps.

- Provides formal proof of untestable logic or justifiable exclusions—critical for completeness.