Siemens Digital Manufacturing with Tooling Design

Integrated, Intelligent, and Automated Tooling Design for Industrial Production

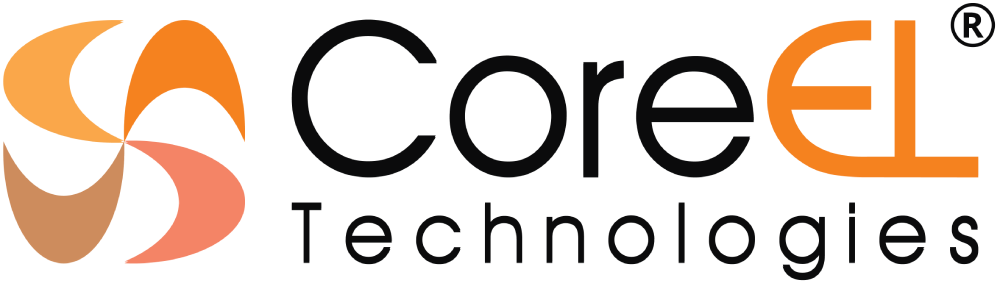

Tooling Design is a critical pillar in the Siemens Digital Manufacturing ecosystem. Siemens offers an end-to-end, model-based tooling design solution within NX and Teamcenter, supporting the development of high-precision molds, dies, progressive tools, jigs, fixtures, and assembly tooling. This tightly integrated solution ensures faster tool development, greater accuracy, and full associativity across CAD, CAM, and CAE domains.

By unifying design, simulation, manufacturing, and data management under one digital thread, Siemens empowers manufacturers to create first-time-right tooling and accelerate time-to-production for industries such as automotive, aerospace, consumer goods, electronics, and industrial machinery.

Key Technical Capabilities of Siemens Tooling Design:

- Parametric Tool Design in NX

- Mold Tooling Design

- Progressive Die Design

- Jig and Fixture Design

- CAE Integration for Tool Validation

- CAM-Ready Tooling Models